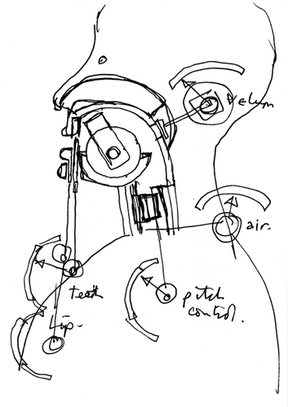

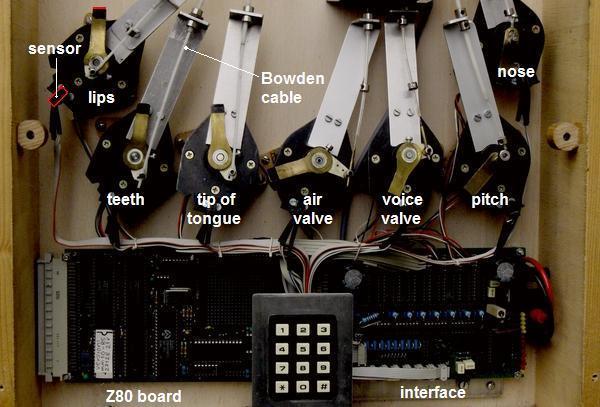

MotorMouth, detail of the head and throat

|

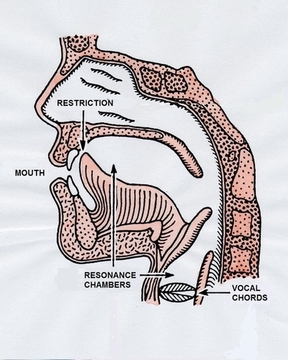

the vocal tract The vocal "cords" are two soft flaps of flesh on opposite sides of the air pipe leading from the lungs. Normally thay are separated - for breathing. When we speak they move closer together, almost touching, and vibrate in the wind flow from the lungs, slapping together to produce the basic unfiltered voice sound. (They can also be tensioned to raise the pitch). The tongue changes this sound by moving backwards, forwards, upwards and downwards inside the mouth cavity, so changing its resonant frequencies. The varying apertures formed by the lips also change the mouth resonances. |

|

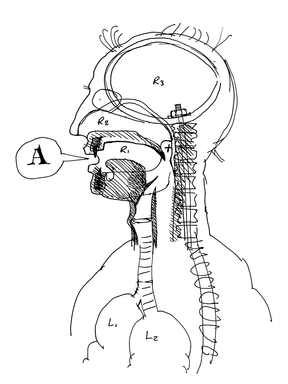

initial sketch MotorMouth is an attempt to reproduce some of the features of the vocal tract using 8 motors. The blade of the tongue can be moved forewards, backwards, up and down. The lips, teeth and nose valve can be opened and closed. |

|

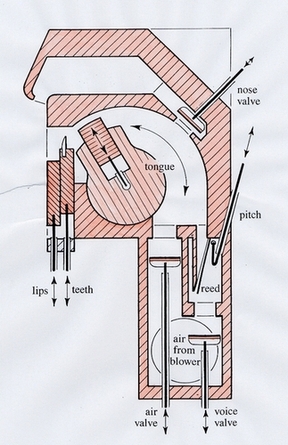

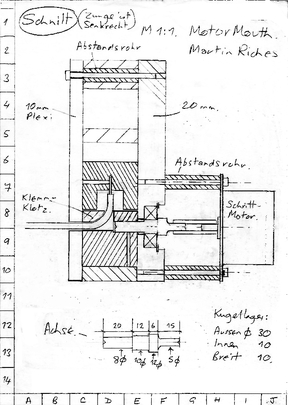

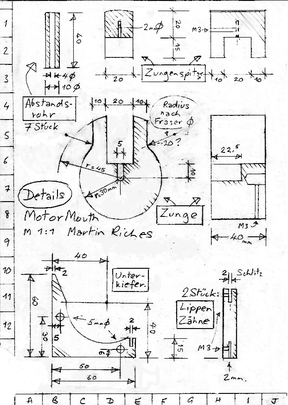

general arrangement drawing As in the case of its predecessor, the Talking Machine, the voiced sounds are produced by a vibrating reed. Unlike humans, MotorMouth has two air supplies: one air valve to vibrate the voice reed and a bypass air valve for unvoiced sounds. These unvoiced sounds, like F, S, T, etc. require much more air than could easily pass through the reed itself. If I was going to do this project again today, I would make the vocal cords in a much more realistic way, probably using a very soft rubber, such as Septon. |

|

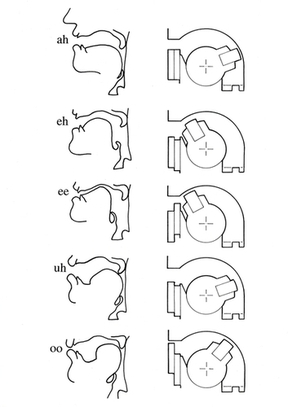

the vowels A comparison of how a human being and MotorMouth speak the vowels. |

|

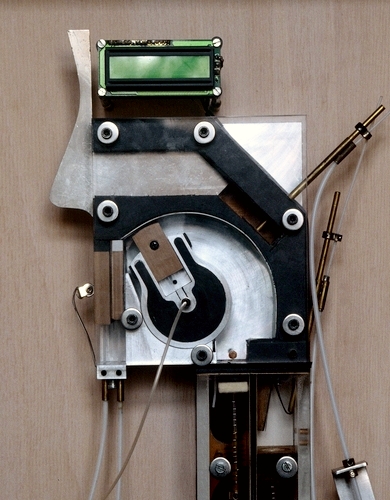

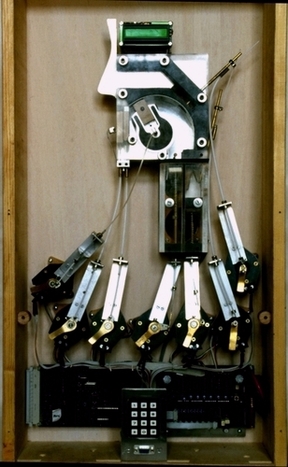

MotorMouth (1996-1999) 8 stepping motors, blower, micro-computer, interface, wooden case. 86cm high. At the top, the head of the machine and, below, the stepping motors that drive it via cranks and bowden cables. The motors are controlled by a built-in Z80 board - the 1990s equivalent of an Arduino. At the time this was a reasonably fast and compact system and I had all the hard- and software available and ready to go. The keypad is used for launching the speech programs and for changing parameters such as overall pitch. Seven motors can be seen below the head. The eighth motor that turns the tongue is on the rear side of the machine and, like the blower, not visible here. |

|

section through tongue and motor The section shows how the tip of the tongue, the "blade", is moved up and down by a Bowden cable. The surfaces of the blade are covered with PTFE coated fabric to reduce friction. The drawing shows a roller bearing for the tongue. In the final design this was replaced by a much wider phosphor bronze bush bearing taking up the entire 20 mm width of the base plate. The clearances between the tongue, chin and base plate are set to about 0.1 mm, |

|

The tongue, chin and base plate were cut from solid aluminium with an industrial CNC milling machine by Michael Buchmann. To make it lighter and easier to move fast, the tongue was hollowed out to within 2 or 3 mm from the outside surfaces and the cavity was filled with a hard polystyrene foam and then sealed. The lips, teeth and the blade of the tongue are made of wood. The blade was also drilled out to lighten it. |

|

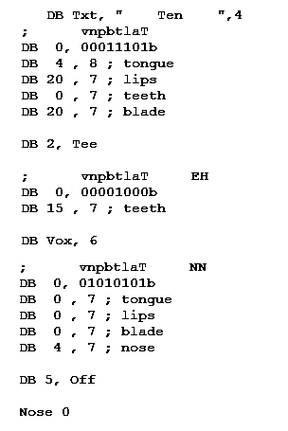

Data: How to say "ten" The eight 1's and 0's under the line vnpbtlaT select which motors will be moved next: voice-valve nose-valve pitch blade of the tongue lips teeth air-valve Tongue The following lines show the position that each motor should go to and its speed. In the case of "ten" there are three stages: T - EH - N. Other symbols such as Tee are shorthand for standard routines, in this case a very quick release of air to say "T". Nose 0, at the end, closes the nose valve. |

|

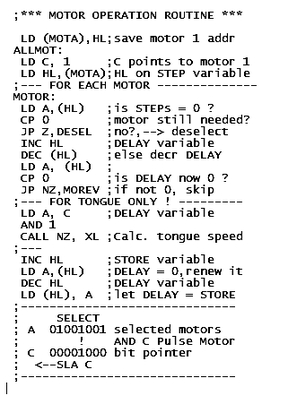

Program: Interpreting the data The Z80 microprocessor is programmed with about 46 pages of heavily annotated assembly code which boils down to about 3 pages of machine code that the Z80 chip can actually understand. About half of this is data: the speeds and positions of the motors that enable the machine to speak, (see above). The other half, the program, seen on the left, is about interpreting that data and driving the motors. Assembly language: "LD A, (HL)" etc. etc. is rather dry but very fast; at the time just fast enough. Today I would use a more comfortable language and a normal, faster computer. |

A successful and ingenious masterpiece by Martin Riches: an artificial speech mechanism using motors, valves, a rotor and a blower that can say How are you? or I love you! at the touch of a button. Its speech may sound a trifle hollow, the voice of a survivor perhaps, but it is fascinating to see how an artificial tongue and lips can produce sounds similar to those of a human being without recourse to any form of recording. It is also somewhat uncanny: the ability to speak is generally taken as a definitive sign of the development of human intelligence but here we bear witness to the articulations of an automaton.

Tom Mustroph Exhibition review, Neues Deutschland, Berlin 16.06.2002

Martin Riches' MotorMouth is not concerned with the shortcomings of human attempts to represent Nature but is rather an audacious attempt at its direct reproduction. Having closely studied the ways of human speech he has transformed them directly into mechanical technology and has succeeded in making a machine that can speak. The machine produces its programmed words without a mechanical accent. Art and Nature are unmistakably reconciled.

Anne Thiem Exhibition review, Berliner Morgenpost 26.08.2002

I found a friendly technical review of this webpage on Hackaday 2017/02/08 reminiscing about Z80 assembler programming. I learnt assembler language in the 1980s on a Sinclair ZX81 and continued using it after most sensible people had graduated to C++ or Python.

Steven Dufresne MotorMouth for Future Artificial Humans, Hackaday 02.08.2017

I was also pleased to find the following text by Heinrich Heine, written in 1834:

The story is told of an English inventor who, having devised the most ingenious machines, finally hit on the idea of constructing a human being. At last he achieved this ambition and the work of his hands was able to behave and comport itself just like a human. It even bore within its leathern bosom something quite like human feelings - not unlike the normal feelings of an Englishman. It could communicate its sensations in articulate sounds and the noises of the internal wheels, ratchets and screws which could then be heard gave it an authentic English accent. In short, this automaton was a Perfect Gentleman and lacked nothing to transform it into a real human being ... except for a soul.

But this the English mechanic was unable to give him and the poor creature, well aware of this deficiency, now tormented his creator day and night with the request to give him a soul. These requests, repeated ever more urgently, became so unbearable that the artist finally took flight from his own creation. But the automaton followed post-haste, pursued him to the continent, caught up with him occasionally and then snarled and grunted at him: Give me a soul!

Heinrich Heine

On the History of Religion

and

Philosophy in Germany

(1834)

Third Book