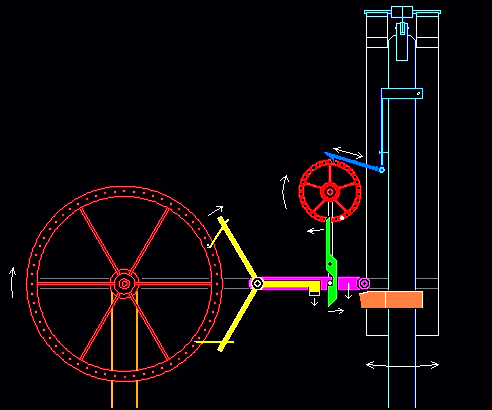

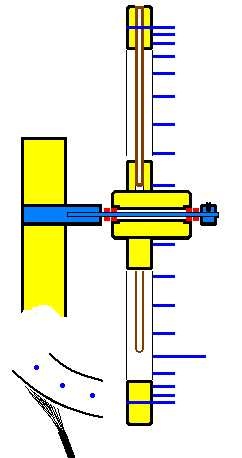

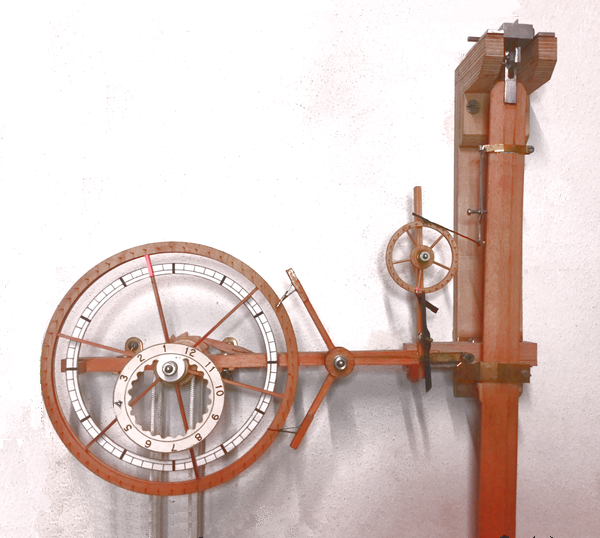

Once every 30 seconds the count wheel of the master clock releases a gravity arm which pushes the pendulum and sends an electrical pulse to move the hands of all the slave clocks. It also switches on two electro magnets that reset the gravity arm ready to give the next push.

Synchronomes also served as slaves for the famous Shortt-Synchronome clocks which were the world's best timekeepers in the 1920s and 30s, installed in many observatories.

These were the first clocks that were more precise than the rotations of the Earth itself. Since the 1940s they have been replaced by quartz clocks and later by atomic clocks. Recently, a Shortt-Synchronome under test has been found to have an error of one second in 12 years.

It is twelve, fifty-eight and thirty-two seconds.

It is twelve, fifty-eight and thirty-two seconds.