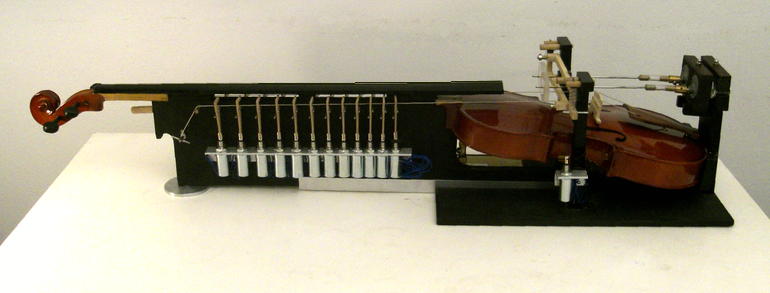

Jon Rose saw my StringThing instruments and, in 2014, asked me to make him an automatic viola. Like the many instruments that he has adapted himself, the body was to be taken from a factory-made instrument, a Mendini MA250.

I have great respect for the Chinese production engineers and crafts-people who produce these factory-made instruments and I felt like a barbarian when I had to take a saw to their splendid new viola. The scroll and fingerboard are included in the new instrument as decoration.

There are just two strings, each bowed by a rosined wheel. The bridge-to-nut distance was extended from the original 42cm to 63cm (the same mensur as a cello and my StringThing) lowering the pitch by a fifth. It has two guitar strings, currently tuned A, 220 Hz, the other a fourth lower, E. Each string is played by 12 electro-magnetic fingers.

The frets are steel rods projecting from the neck. A similar set of rods guide the fingers. They are positioned to allow each finger 1 mm of play, just enough to prevent them sticking. The holes for the frets and guide rods were drilled with a CNC machine. The data for the positions of the frets came from Luitaio Mottola.

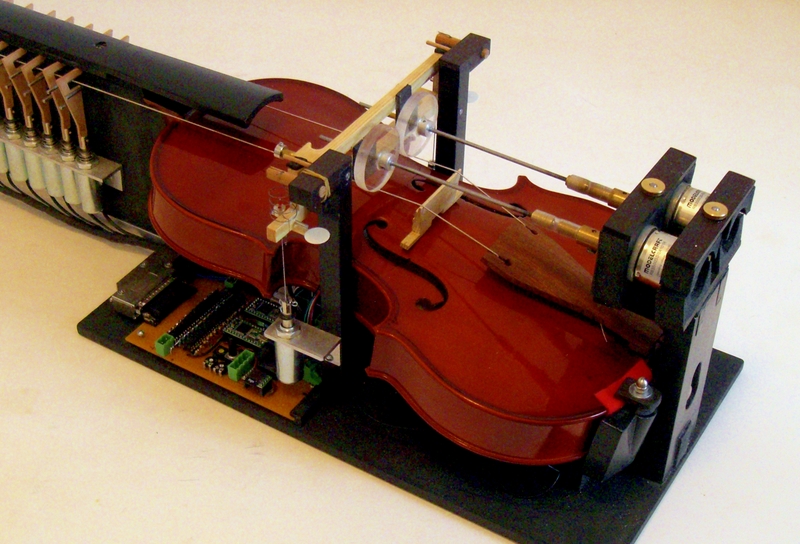

Some fingers, the electronics and the bow wheel mechanism The small white disk is the target for an IR bow-position sensor. The wood chassis is stained and lacquered to match the original fingerboard. Other details, like the new two-string tailpiece, are made of tropical hardwood.

Electronics and software by Sukandar Kartadinata

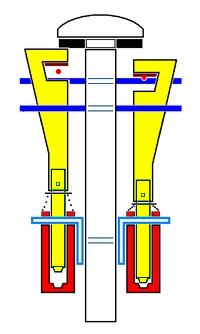

Unlike my previous instruments where most of the actuators are switched either ON or OFF, the real innovation lies in

Sukandar Kartadinata's electronics: the pressure of the fingers, and - more importantly - the pressure and speed of the bow wheels can all be varied. This makes it possible to vary the volume, the attack and the timbre. The technique used is Pulse Width Modulation. Briefly, the current is sent to the accuator at a high frequency in a series of ON/OFF pulses whereby the pulse can be varied from a long ON and a short OFF (strong), to a short ON and a long OFF (weak).

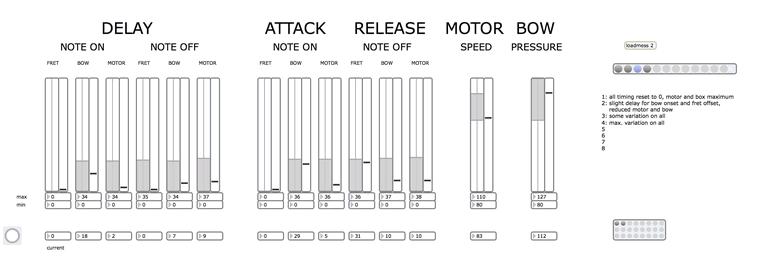

This is a tool, designed by Sukandar, that was used during the software development to optimise the movement of each finger and the various speeds and pressures of the bow wheels.